Alent Drying AB

Technology

Cleantech Timber drying.

Cleantech used new technologies that are energy efficient and sustainable. Alentpumpen with the slogan "Stop the fans for better drying" is very much cleantech.

Cleantech used new technologies that are energy efficient and sustainable. Alentpumpen with the slogan "Stop the fans for better drying" is very much cleantech.

Alentpumpen affect the wood in several aspects that promote water transport inside the timber without building up excessive stress in the wood. Short periods at full wind speed and full ventilation removes surface moisture effectively. Together, this means quick and easy drying.

Alentpumpen is based on physical properties in the wood which makes drying quicker with pumping than when it blows hot air all the time over the wood surface. With inflation kept surface fresh, not dried out, and it promotes moisture evaporation. Expertise would say that the evaporation zone is closer to the surface when pumping.

Another important success for the Alentpump, is the temperature driving force that reverses direction during the stop. The vaporization is still going on at the timber surface during the shutdown, but now the heat comes from the wood instead of from the hot wind. We get a temperature gradient in the timber where the surface is colder than the timber's interior. It is the vapor pressure that drives the water diffusion towards the surface and the vapor pressure is a product of the temperature and moisture content. We always have a higher moisture content in the interior of the timber and it drives moisture migration, diffusion, out to the surface. When the temperature is higher in the interior of the timber than on the surface this increases the moisture migration towards the surface. In conventional drying, heat is constantly higher on the wood surface, keeping the temperature driving force in the wrong direction.

Another important success for the Alentpump, is the temperature driving force that reverses direction during the stop. The vaporization is still going on at the timber surface during the shutdown, but now the heat comes from the wood instead of from the hot wind. We get a temperature gradient in the timber where the surface is colder than the timber's interior. It is the vapor pressure that drives the water diffusion towards the surface and the vapor pressure is a product of the temperature and moisture content. We always have a higher moisture content in the interior of the timber and it drives moisture migration, diffusion, out to the surface. When the temperature is higher in the interior of the timber than on the surface this increases the moisture migration towards the surface. In conventional drying, heat is constantly higher on the wood surface, keeping the temperature driving force in the wrong direction.

Another advantage for the Alentpump is mechanosorption, ie that the timber is subjected to alternating tension and relaxation (stretching and relaxation). It also promotes moisture migration according to researchers.

A fourth advantage is that the bonding energy that holds a water molecule to the cell wall is lower at higher humidity, Pumping gives higher surface moisture resulting in less energy to move the water molecules to the surface.

Alentpump is thus not magic - it's cleantech and its benefits have physical explanations and we have proved Alentpump superiority in 7000 batches of drying in full scale!

Condensation Panel saves energy and dries faster

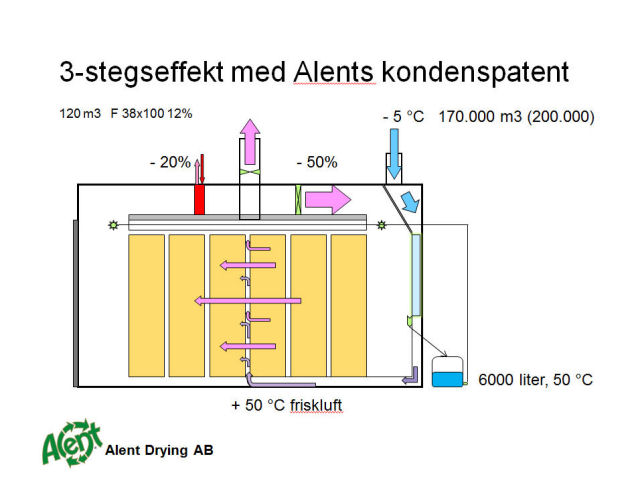

Condensation panels fold out water vapor from the circulating drying air. For a larger timber cargo, about 30 tons of water has to be evaporated from the wood surface and vented out of the dryer.

Condensation panels provide several tons of water, thereby reducing ventilation requirements significantly. When water vapor condenses inside the dryer it generates condensing heat  and reduces heat demand.

and reduces heat demand.

During the first drying phase it is either heat or ventilation capacity that limits the rate of drying. With condensation panels may dryer significantly higher capacity allows the initial drying phase can be shortened.

Alent Drying does attempt to optimize the drying process so that condensation panels utilized to an even greater degree. To blow dry heated outdoor air from below the middle of the drying rate is a new idea 'from Alent. We hope to reduce heat consumption by 20% while dry faster and with less spread through the load.

Alentpumpen is a new drying principle that uses condensation panels optimally. At the same time saves electricity.

Online Soft Sensor for Wood Moister Content

Timber drying is one of the most difficult processes to control, depending on thousands of individuals in a batch with a wide range of input data like input moister content, density and structure of the wood. Researchers and  technicians are searching for a method of measuring the moister content in the whole batch, good enough for controlling the drying and stopping at the required final moister content. The Alent Pump opens new opportunities to control the drying process and to measure the wood moister content. After several years of research and development, Alent is now ready to present a new solution, the Alent Softsensor for Wood Moister Content. The Alent Softsensor presents the estimated mean value of wood moister content for the whole batch during drying. The confidence region, or the accuracy, seems good enough to end the drying without the need of manual measurements.

technicians are searching for a method of measuring the moister content in the whole batch, good enough for controlling the drying and stopping at the required final moister content. The Alent Pump opens new opportunities to control the drying process and to measure the wood moister content. After several years of research and development, Alent is now ready to present a new solution, the Alent Softsensor for Wood Moister Content. The Alent Softsensor presents the estimated mean value of wood moister content for the whole batch during drying. The confidence region, or the accuracy, seems good enough to end the drying without the need of manual measurements.

Alents drying software, AlentDryTec,

"the best" according to users

The system is specially made for customized drying with drying schedule development and a library where you can keep track of a large number of schedules versions. The system is also made for all types of kilns.

The software is based on standard products and have a server - client solution for PC under Windows 7. The code is generalized to be able to run in any modern PLC systems. With this approach Alent can support the system via the Internet and customers can feel confident that the hardware can be installed and supported by local businesses and self-service.

Pumpsim

Alents control system includes a calculation module, Pumpsim which calculates drying schedules specific to customer requirements.

Alent Power

Alent Power is an option that synchronizes several kilns so that the power output from the boiler and the electricity network is minimized without interrupting the drying process in individual kilns.

Alent Power takes into account the installed capacity of the dryers controlled by Alent. Sawmills with many kilns and power contracts can reduce electricity costs significantly with AlentPower.

New features is that maximum demand can be scheduled for interaction with other consumers and weekends. The resulting total consumption of electricity and heat energy are presented in history along with a graphical view of all the dried batches. A new feature in Alent Power run with active compensation of the drying processes to minimize disturbance on the prioritized batches.

Technology

Questions about Alents products ? Give us a call at +46(0)920-10060.