Alent Drying AB

Home

Staffan Ruuth, new CEO at Alent Drying AB Staffan Ruuth is the new CEO at Al |

Alent Drying control systems - an international success.

|

|

The Alent control system was a success at the LIGNA fair 2015. 11 systems were sold during the fair and another 30 were sold abroad during July. OS Panto manufactures kilns in stainless steel with Alent control system. This attracted many visitors to the Alent stand. A dozen other kiln manufacturers visited us to learn more about the AlentPump and our complementary patents solutions. We are now receiving inquiries for new kilns with Alent control system, in which we can provide valuable information to the customer depending on their preference. Professor Thomas Gustafsson's education in dynamic drying control was much appreciated and applauded by the visitors. |

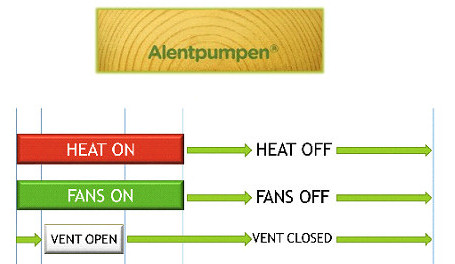

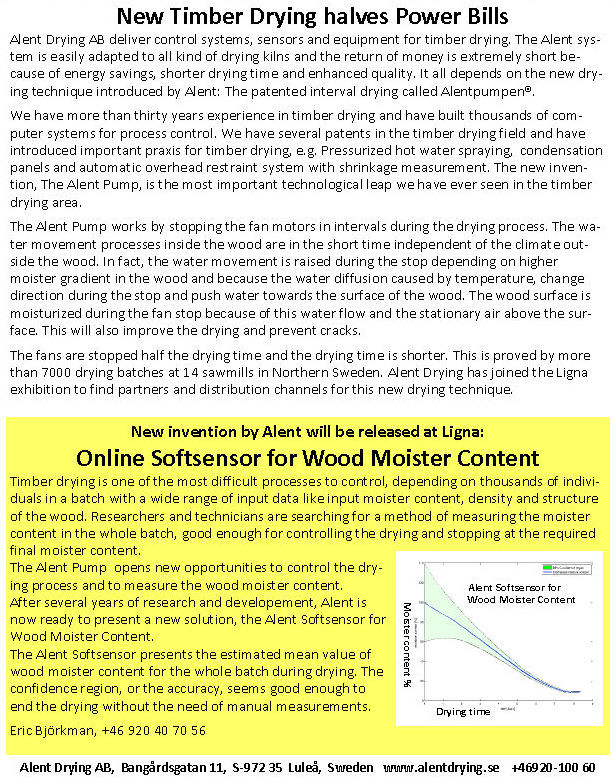

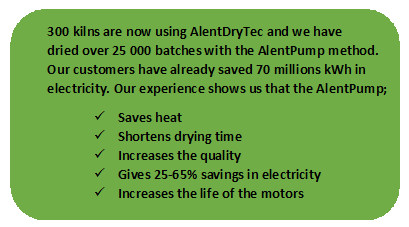

Alents technology for wood dryingThe AlentPump is a new patented method to dry wood. It is based on alternating hard and soft drying. In practice this means that controlled fans, heat supply and ventilation in intervals whose length changes as drying progresses. The AlentPump saves about 50% electricity while drying time is considerably shorter and the quality is better than conventional wood drying. Alents' interval drying is an optimal combination of natural processes in wood and dynamic rule technology. There is no hocus pocus, just a new way of thinking. The goal for Alent is to be world leading within control systems for wood drying and support. Alent control system is based on standard PLC from Omron, Siemens e t c. It is easy to install and very reliable. Our contactless online moisture meter makes wood drying even more accurate. |

|

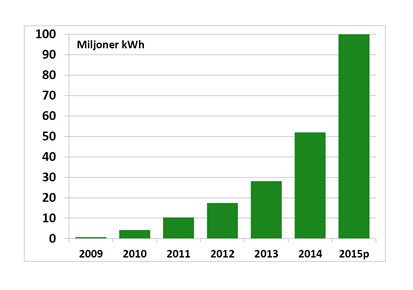

70 millions kWh in electricity have been saved in kilns using the Alent control system |

|

Alent Drying, The jury's verdict: With an innovative solution, and looking towards the future, the winning company develops for a traditional primary industry. Alent Drying helps the sawmill industry both to halve the electrical consumption and increase the quality of the final product. The company is a shining example of effective energy and sustainability work that now attracts much attention, not only in the country but also internationally. |

Kiln Operation Manager Lennart Nilsson has used the Alent control system for a long time. He sees this continuing investment to Alent as very positive.

|

Stenvalls Trä AB buys more.Stenvalls Trä AB in Sikfors place orders for additional control systems from Alent. This means that they are now running Alent control system in all kilns. They continue to use Alents contactless online wood moisture content meter, WMC.

At Lövholmen there are tests started with Alent control systems in two rebuilt progressive kilns. We are also reconstructing the continuous feeding system. |

FPInnovations representatives visit Alent and expressed interest in exploring opportunities for the Alent Pump technology in Canada.

Luiz Oliveira, Research Leader at FPInnovations in Vancouver BC, Canada and Marc Savard, Researcher in Québec QC, Canada here together with the Chaired Professor Diego Elustondo at Luleå technical university in Skellefteå. Luiz and Marc are visiting Sweden to look into drying technologies that could be of potential interest to Canadian lumber producers. They visited the Alent head office in Luleå and our branch office in Skellefteå. Both Luiz and Marc are co-authors of the comprehensive drying handbook for the Canadian wood industry and have worked extensively with the industry. They were impressed with our systematic working methods for developing the AlentPump. |

|

Ladenburger GmbH change all kiln control systems to Alent!

Ladenburger GmbH Germany, installed and evaluated Alent control system in one kiln. They could soon see the benefits with the system, and quickly installed more. Now they are running Alent control system in all kilns at both of the sawmills.

|

OS Panto - Alent Drying ABOS Panto is one of the biggest Kiln Producers in the world and Alent Drying is a leading developer and producer of Kiln Control Equipment. Now these two companies has decided to cooperate in the field of wood drying and a first order will be installed in France this week.

|

Alent Drying AB

![]()

Alent in Media

Pfeifer Holz in Germany invested in Alent

The investment that Pfeifer Holz made in Alent Drying control systems in Unterbernbach has paid off well. It is shown clearly by the good result. The installation was made in May 2015 .

2015-08-25

Bergs Timber Orrefors

Bergs Timber moves ahead and installs 5 Alent control systems at Bergs Timber Orrefors. Alent control systems are already running at Bitus and Gransjöverken. They are also reviewing their kilns at Orrefors and installs Alent Premo, pressurised hot water system.

2015-05-14

Sandåsa

Sandåsa bought 4 control systems from Alent during the LIGNA fair. They are already up and running, despite the holiday season and have had time to run a few batches. Welcome Sandåsa!

2015-05-04

Siljan Blyberg Timber AB

We welcome yet another group to Alent.

Now Siljan Blyberg Timber AB also installs Alent control systems in their kilns.

2015-04-30

Ansgarius Svensson AB proceed with Alent

Ansgarius Svensson AB in Södra Vi, is now switching to Alent control system in all their batch kilns.

Ansgarius Svensson delivers untrimmed board of high quality scotch pine and are very focused on quality.

2015-04-24

Kurt Lagergren proceed with Alent

Kurt Lagergren has during a shorter time tested the Alent control system in their cross-circulation kiln. Today, they have decided to go ahead and replace all control systems in their batch kilns to Alent. At the same time they install Alent Premo, pressurised hot water system.

2015-04-23

NK Lundström upgrade again

NK Lundström now replaces the last 4 control systems to Alent in their batch kilns.

2015-03-23

Moelven changes to Alent

Yet another big group has chosen to start drying with new technology, the AlentPump.

2015-03-16

AB Okome changes to Alent

Alent continues to expand in southern Sweden. AB Okome also changes their control systems to Alent.

2014-11-24

Kurt Lagergrens changes to Alent

Alent continues to expand in southern Sweden. Kurt Lagergrens Timber AB now changes to Alent control system in their cross-circulation kiln.

![]()

2014-11-10

Ansgarius Svensson AB buys Alent control systems

Ansgarius Svensson AB in Södra Vi, upgrades their batch kilns with Alent control system, contactless online moisture meter and Alent Premo pressurised hot water system.

2014-10-27

Stenvalls Trä buys more

Stenvalls Trä AB in Sikfors now dries with Alent control system in all their batch kilns.

2014-08-29

Martinsons proceed with Alent control system

After testing Alent control system, Martinsons Group chooses to replace all control systems in their batch kilns to Alent.

2014-08-27

AB Karl Hedin proceed with Alent control system

Karbenning Sawmill & Planing that is belonging to the AB Karl Hedin Group is replacing all their batch kiln control systems to Alent.

2014-08-14

Fyrås Trä places yet another order

Fyrås Trä has dried with Alent for several years and are now upgrading to Alents latest version. They will upgrade yet another kiln with Alent control system and install AlentPremo pressurised hot water system.

2014-07-17

Karbenning Sawmill & Planing goes ahead and replaces all the control systems to Alent

- We are proud and delighted to once again gain a new confidence from AB Karl Hedin in Karbenning, who have high demands on the quality and availability of drying says Thomas Landström seller at Alent Drying.

We have now used Alents control system for 7 months. We find it very confidently to work with Alent and their control system, furthermore have their support worked well. We have seen that the timber maintains a good quality and it has become shorter drying times, says Thomas Karlsson, Quality Manager at Karbenning. Therefore, we have today placed an additional order of 12 control systems.

We are very happy that AB Karl Hedin proceeds with Alent after comparing quality for a longer time. It also feels extra good to hear that our support is appreciated says Thomas Landström.

2014-07-10

OS Panto delivers 7 new kilns with Alent control system to France

Now is the production of new batch kilns with Alent control system started.

![]()

2014-07-01

Italian kiln producer OS Panto in cooperation with Alent

OS Panto has now decided to use Alent control system in there batch kilns.

2014-06-27

Edsele Såg chooses Alent

Edsele Såg now replaces all control systems in their kilns to Alent.

2014-06-25

Bergs Timber Bitus upgrades again

Bergs Timber Bitus takes additional kiln in operation with Alent control system.

2014-05-10

Ladenburger in Germany change to Alent

After quality and energy saving tests Ladenburger decides to change control system to Alent in all kilns at both sites.

2014-04-30

Martinsons place order for additional control systems

Martinsons have been testing Alent for a time, and is now putting orders for additional control systems.

2014-03-14

Bergs Timber Bitus change to Alent

Bergs Timber Bitus AB install Alent control system in all their batch kilns.

2014-02-14

Large group signs new major order of control system

After testing 12 Alent control systems during a few months, Ladenburger chooses to install in yet another sawmill earlier than anticipated.

2013-12-16

Stenvall buys additional Alent pressurised hot water system

Stenvalls Trä buys AlentPremo, pressurised hot water system to additional 6 batch kilns in Sikfors.

2013-12-17

AB Karl Hedin buys Alent control system

Karbenning Sågverk & Hyvleri within AB Karl Hedin group changes 4 control systems to Alent.

2013-12-13

Stora Enso Timber changes from steam to Alent Premo pressurised hot water system

Stora Enso Timber in Ala stop using steam and installs AlentPremo, pressurised hot water system in all 21 kilns.

2013-11-27

Stora Enso changes to Alent

Stora Enso in Ala, changes their control systems to Alent in 21 batch kilns after that themselves have measured heat and electrical consumtion.

2013-10-29

Large order and international breaktrough

Ladenburger in Germany orders 11 Alent control systems. Both the drying quality and electrical savings were convincing after just a few week testing of the Alent control system.

2013-10-25

Alent opens office in new town, Skellefteå

Pär Wiberg, PhD in Wood Physics begins at Alent. He will work on the development of timber drying and customers support from Alents office in Skellefteå.

2013-10-10

Setra buys additional 7 system

Setra Rolfs in i Kalix have been running 6 Alent control systems during 2013 and are now ordering 7 additional control systems.

"Electricity savings and the reliability was the motive for us earlier this year when we switched to Alent control system. Now, earlier than anticipated we change to Alent in another 7 kilns as it turns out that Alent dried timber provides higher quality, says Anders Olofsson, manager Setra Rolfs".

2013-09-26

Bennsäters Sågverk change to Alent

Bennsäters Sågverk buys Alent control system and AlentPremo, pressurised hot water system to 3 kilns.

2013-09-20

Setra Malå buys additional 6 Alent control systems

Setra Malå upgrades additional 6 kilns with Alent DryTec.

2013-08-09

Brännfors Träförädling very pleased with Alent DryTec

Stefan Edström owner of Brännfors Träförädling have now been using AlentDrytec during a year in 4 batch kilns with good resaults. "I have noticed that during this period of time the quality have been much better and the heat consumtion is about 10% lower. It pleases me with own boiler as all savings are really good. It facilitates if you do not need to refuel that often"

2013-07-04

Stora Enso upgrades

Stora Enso, Ala upgrades 6 ABB kilns with new fan blades and ny actuators.

2013-06-28

Bäckebo change to Alent

Bäckebo sågverk sign new order on 8 batch kilns. They also buy AlentPremo pressurised hot water system.

2013-06-18

Order from Germany

One of Germany's biggest sawmill group have just bought its first Alent control system.

2013-04-24

Setra upgrades again

Setra Rolf will proceed with Alent control system in additional 4 batch kilns. This decision is taken after they have been running their first three Alent control systems for three months.

2013-03-15

Höglandssåg buys Alent

Höglands Såg has 6 Alent control systems in Anundsjö and is now buying 6 additional control systems for batch kilns. These kilns have both condensation aggregates and hot-air drying.

2013-02-27

Martinsons buys Alent

Martinsons buys Alent control system for 3 batch kilns in Kroksjön.

Tobias, Martinsons in Kroksjön, is very pleased with the quality after just a short start-up period. "Today we dry 63x75 mm planks without cracks and with short drying times!" We will continue developing drying together.

2013-02-25

Stenvalls buys Alent pressurised hot water system

Stenvalls Trä buys AlentPremo, pressurised hot water system for batch kilns in Sikfors.

2013-01-31

Brännfors Trä upgrades again

Brännfors Träförädling continuing with further 2 more Alent control systems, this time in Incomac-kilns. Alent has also delivered fans and motors.

2012-12-11

Setra Rolfs buys Alent

Setra Rolfs Såg buys 3 Alent control systems for uppgrading of batch kilns.

Håkan Eliassson, Kiln Operation Manager at Setra Rolfs , is impressed by the quality, drying times and electrical savings. After running Alent control system in 3 batch kilns three months Setra Rolfs has decided to buy further 4 Alent control systems.

2012-11-29

Brännfors Trä buys Alent control system

Brännfors Träförädling buys 2 alent control systems.

Questions about Alents products ? Give us a call at +46(0)920-10060.